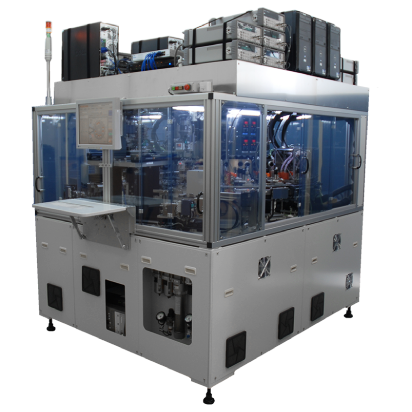

Active Alignment Machine (Magazine Type)

- Control No

-

- AKV644A

-

- Patent No5610658

- Patent No5747396

Model No.

AAAS860M

Descriptions

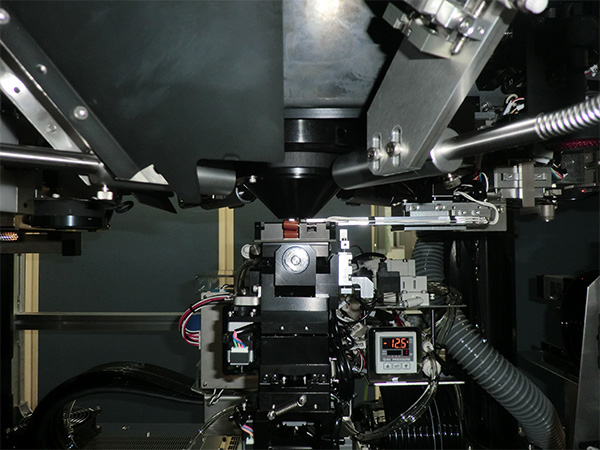

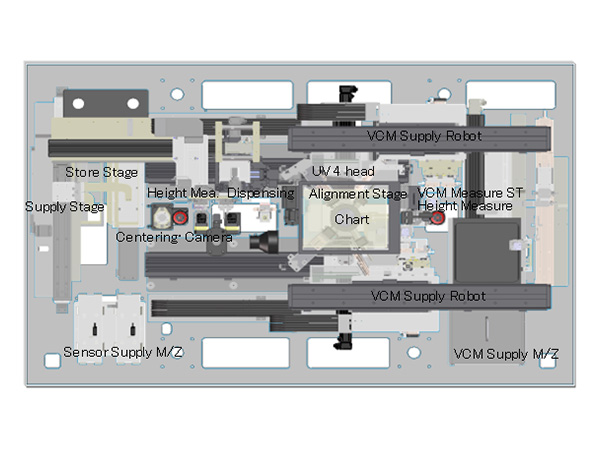

This machine mounts the lens unit to the sensor substrate which are supplied via special trays. It performs focus adjustment, temporary bond curing, and storing under automated opearions. Enables user to adjust forcus with a high degree of accuracy via 6-axis alignment functions.

Features

- Automatically supplies and discards materials via trays and magazines.

- Enables user to perform alignment with a high degree of accuracy, as adjusting 6-axis alignment at the CMOS sensor side, while keeping the lens optical axis.

- Performs active alignment in the order of the processes at turn on electricity to the VCM unit, measures height via a displacement meter, and maintains the driving condition onto the origin point of lens. It, then performs active alignment by changing the current amount.

- Detects foreign material (black point) via white color imaging inspection on LED light prior to performing the processes of active alignment and dispensing of bond.

- Protects from dust generation by using linear motor for transferring robot with a long stroke.

Specification

| Compatible Work | Camera Module |

|---|---|

| Secure Accuracy | X,Y Direction less than ±5μm |

| Cycle Time | Z Direction less than ±1μm θ Direction less than ±0.5° 19. 6 sec. per pc. (reference UPH 155/H) |

| Outer Dimension | W1800XD1200XH1700㎜ (excludes monitor, indicating light, and height is according to chart instalation height) |