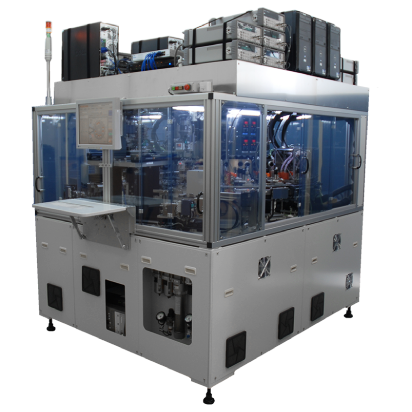

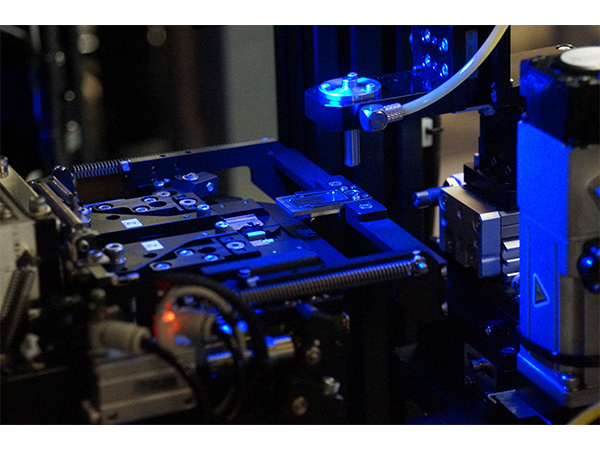

Active Alignment Machine

- Control No

-

- AKV645A

-

- Patent No5610658

- Patent No5747396

Model No.

AAAS860I

Descriptions

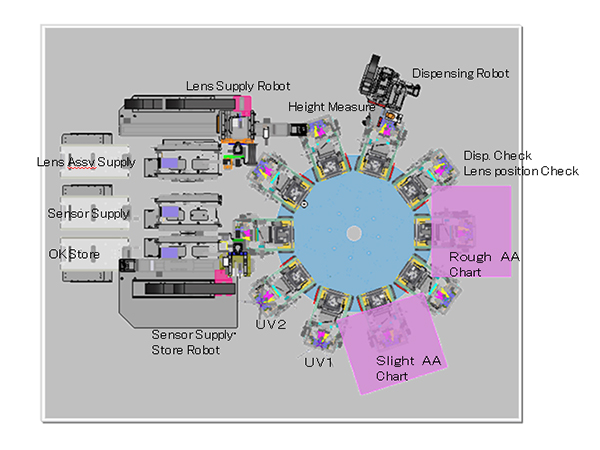

Adjusts the focus and the optical axis for CMOS sensor and lens assembly via 6-axis alignment unit on the index table. It, then temporarily secures bond via UV irradiation.

Features

- By parallelizing main processes such as supply sensors, dispensing bond, Rough_AA, Slight _AA, UV irradiation 1, UV irradiation 2, and storing, performs efficient operations with composing the minimum alignment stage.

- Enables user to achieve a high UPH, by optimizing the adjustment algorithm.

- 6-axis alignment unit is composed with the high resolution actuator.

- Enables user to simplify the GRR analysis and management for AA process, as the machine is not intended to have the multiple AA processes for the purpose of improving ability. (Enables to control the variations between AA processes.)

Specification

| Compatible Work | Camera Module |

|---|---|

| Secure Accuracy | X,Y Direction less than ±5μm Z Direction less than ±1μm θ Direction less than ±0. 5° |

| Cycle Time | 5.0 sec. per pc. (referenceUPH 684/H) |

| Outer Dimension | W1900XD2300XH2500㎜ (excludes monitor, indicating light, and height is according to chart instalation height) |