-

Lens Assembling Machine (24-Head x 2 Index Type)

- Picks up lens parts via a supplying robot, measures the lens gate position via a camera, and supplies them into carriers on the index table.

- Enables users to perform multiple dispensing and circumference dispensing via the bond dispenser unit.

- Performs UV irradiation through pressurization via a pressure pin, and performs temporaly curing of the bond. Performs UV irradiation at 3 stations in order to shorten cycle time.

- Accommodates both the drop-in or build-up approach, by changing the supplying order for each parts.

-

Lens Assembling Machine (32-Head Index Type)

- Picks up lens parts via a supplying robot, measures the lens gate position via a camera, and supplies them into carriers on the index table.

- Enables users to perform multiple dispensing and circumference dispensing via the bond dispenser unit.

- Performs UV irradiation through pressurization via a pressure pin, and performs temporaly curing of the bond. Performs UV irradiation at 3 stations in order to shorten cycle time.

- Accommodates both the drop-in or build-up approach, by changing the supplying order for each parts.

-

Lens Assembling Machine (In-Line Type)

- Enables user to work with up to 9 parts without changing sizes of machine.

- Picks up lens parts via a supplying robot, measures the lens gate position via a camera, and supplies them into carriers on the index table.

- Enables users to perform multiple dispensing and circumference dispensing via the bond dispenser unit.

- Performs UV irradiation through pressurization via a pressure pin, and performs temporaly curing of the bond. Performs UV irradiation at 3 stations in order to shorten cycle time.

- Accommodates both the drop-in or build-up approach, by changing the supplying order for each parts.

-

Lens Assembling Machine for Automotive (with ATC Head)

- Sets nozzle for using parts of each lens (as one set) to the machine in advance. Enables user to exchange nozzles automatically due to the automated nozzle exchanigng function.

- Allows user to maintain a good operation rate due to the automated nozzle exchanging function.

- Performs pressurizing, dispensing bond, and UV curing on the index.

-

Lens Assembling Machine

- Supplies each parts to the mounting stage by operators continuously.

- Checks the parts position in the trays via camera, on picking up parts from trays. Arranges to match direction of parts by performing θroration during transferring parts, which having directivity.

- After completing one kind of parts supply, tray exchange is performed by manaal operation.

- For the products to be mounted by build-up process, performs press-fitting operation to the degree not to fall out, through pressing a certain laod, on supplying barrels.

-

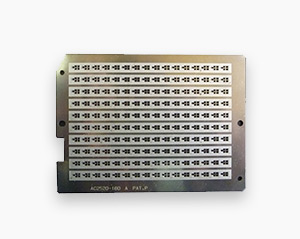

Lens Pressuring, Dispensing, UV Irradiatioon Machine (Square Type)

- Supplies the lens unit with the barrel assembled, pressurizies, dispenses bond, and irradiates UV. Enables user to load one part (optional) in the event of the need to load parts after dispensing bond.

- Transfers via jig carriers in order and processes at each process simultaneously. Supplies Unit→Pressurizing, Hight Measurement→Front-Back Inversion (on build-up)→Checks Unit Position Camera)→Bond Point Dispensing→Loading Parts→Pressurizing, UV Irradiation, Height Measurement→UV Irradiation (Temporary Curing)→Checks Unit Position (Camera)→Dispenses Bond for Whole Circumference→UV Irradiation (Main Curing)→Checks Bond Condition (Camera)→Stores Unit→Discharges NG, Cleaning→Checks Remaining Detection (Camera)