-

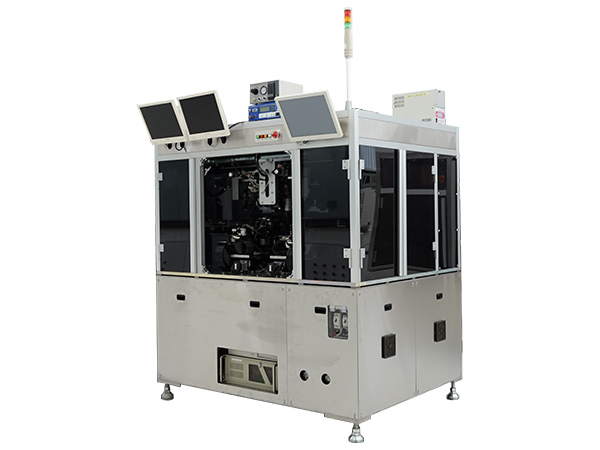

Active Alignment Machine (Single Type)

- Secures the lens barrel unit with dispensing bond to the imaging sensors

- Dispenses UV bond to sensors and performs active alignment via the lens and chart. Performs temporary bond curing by UV irradiation.

-

Active Alignment Machine (Magazine Type)

- Automatically supplies and discards materials via trays and magazines.

- Enables user to perform alignment with a high degree of accuracy, as adjusting 6-axis alignment at the CMOS sensor side, while keeping the lens optical axis.

- Performs active alignment in the order of the processes at turn on electricity to the VCM unit, measures height via a displacement meter, and maintains the driving condition onto the origin point of lens. It, then performs active alignment by changing the current amount.

- Detects foreign material (black point) via white color imaging inspection on LED light prior to performing the processes of active alignment and dispensing of bond.

- Protects from dust generation by using linear motor for transferring robot with a long stroke.

-

Active Alignment Machine

- By parallelizing main processes such as supply sensors, dispensing bond, Rough_AA, Slight _AA, UV irradiation 1, UV irradiation 2, and storing, performs efficient operations with composing the minimum alignment stage.

- Enables user to achieve a high UPH, by optimizing the adjustment algorithm.

- 6-axis alignment unit is composed with the high resolution actuator.

- Enables user to simplify the GRR analysis and management for AA process, as the machine is not intended to have the multiple AA processes for the purpose of improving ability. (Enables to control the variations between AA processes.)

-

Active Alignment Machine (for Automotive)

- Automatically supplies and discards materials via trays and magazines.

- Enables user to perform alignment with a high degree of accuracy, as adjusting 6-axis alignment at the CMOS sensor side, while keeping the lens optical axis.

- Dispenses UV bond to sensors and performs active alignment via the lens and chart. Performs temporary bond curing by UV irradiation.