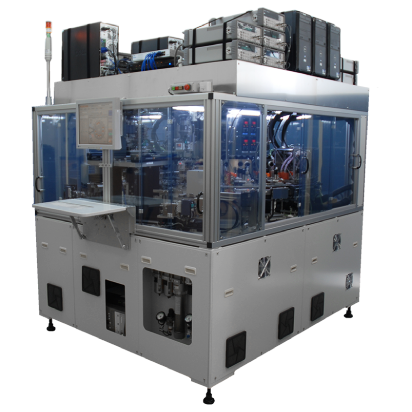

Vacuum Annealing Machine

- Control No

-

- AKV607A

-

- Patent No6056079

Model No.

AANL860I

Descriptions

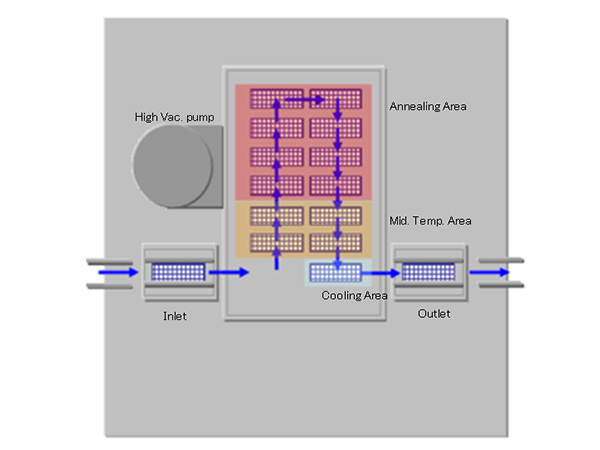

This system performs vacuum annealing on the packages immediately prior to performing lid tacking or seam welding processes. Enables to perform processing in each carrier, to adjust anneal processing speed to welding processing speed.

Features

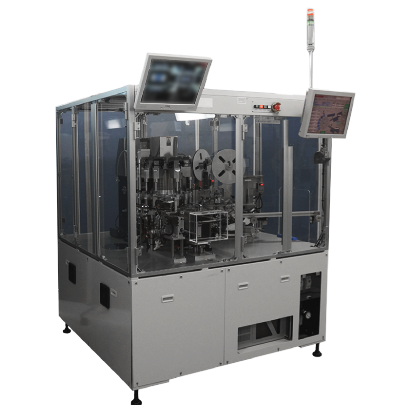

- Compatibility by connecting In-Line system to preceding processes enabling user to perform process by a unit of 1 piece tray.

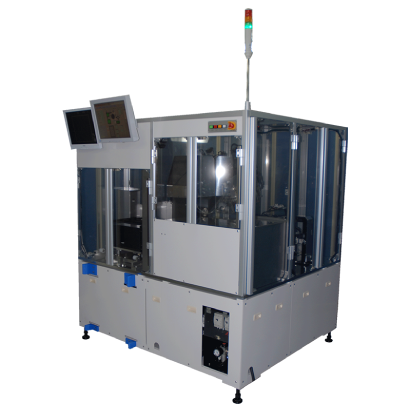

- Anneals ceramic packages under high vacuum conditions of 1.1 x 10-3Pa.

- Heats for 60 minutes at maximum temperature of 300℃.

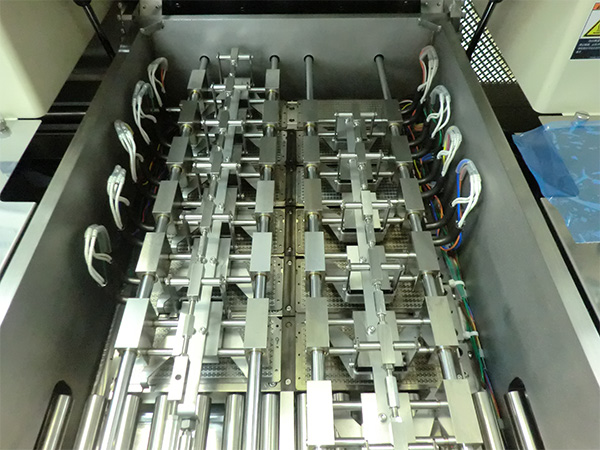

- Transfer jigs accommodate both standard trays and clamp carriers.

- Sets up buffer stocker for stopping time on the post process at the inside of the vacuum chamber.

Specification

| Compatible Works | SMD crystals, crystal oscillators |

|---|---|

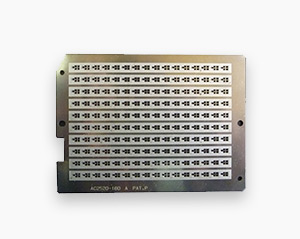

| Supply Lids | Standard Tray 170×134㎜ (600pcs. per tray ) (in case of size under 2016) |

| Vacuum Exhaust System | Degree of Vacuum 1 x 10-3Pa (dry pump + turbomolecular pump) |

| Outer Dimension | W1100XD1300XH1700㎜ (excludes monitor, indicating light, and chiller placed separately) |