Dual Axis Vacuum Seam Welding Machine

- Control No

-

- AKV608A

-

- Patent No4520474

- Patent No5802920

Model No.

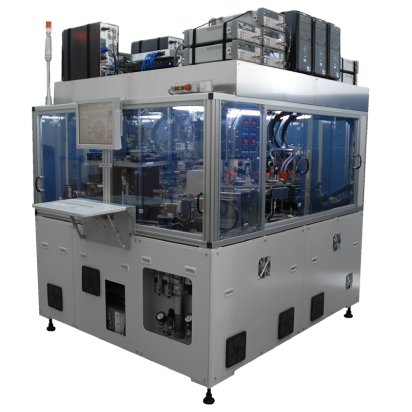

ASSS860I(In-Line Type)

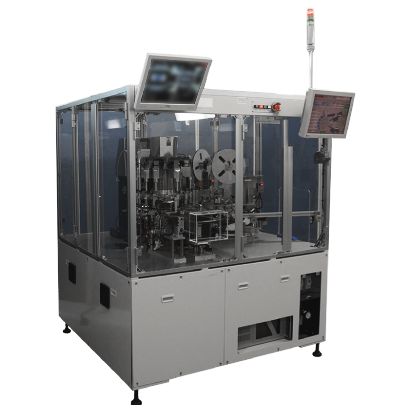

ASSS860M(Magazine Type)

Descriptions

This machine performs seam welding on the X and Y sides of products on which lid tacking has already been implemented. This reduces the running cost of N2 when compared with conventional machines.

Features

- Performs seam sealing on ceramic packages under high vacuum conditions of 1.1 x 10-3Pa

- Conserves running cost of N2 (up to 200-300K JPY per month).

- Accommodates standard transfer jigs (174 x 134 mm)

- Contributes to the maintenance of operations rates by providing automated electrode roller exchanging function.

- Improves the detection of abnormalities by welding current monitoring function.

- Attains rapid recovery from a shutdown due to power failure by employing a turbo molecular pump for the main vacuum pump.

Specification

| Compatible Works | SMD crystals, crystal oscillators |

|---|---|

| Vacuum Exhaust System | Degree of Vacuum 1 x 10-3Pa (dry pump + turbomolecular pump) |

| Cycle Time | 0. 6 sec. per pc. |

| Outer Dimension | W1700XD1400XH1700㎜ (excludes monitor and indicating light) |