Clean Curing Oven

- Control No

-

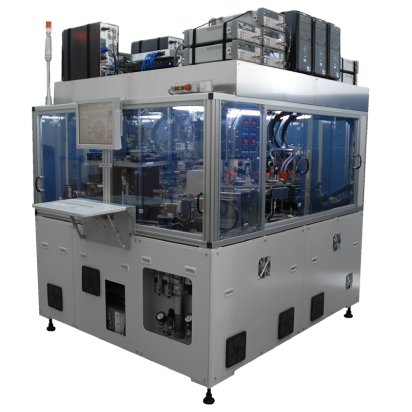

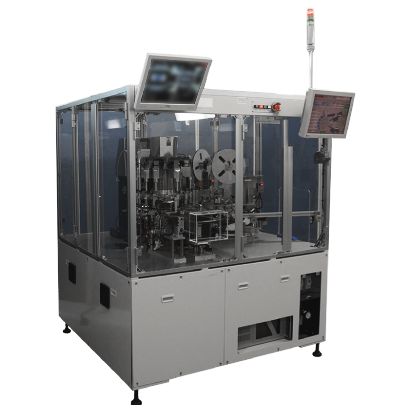

- AKV605A

Model No.

AOVN860

Descriptions

This machine heats and hardens adhesive after loading blanks under Class 100 conditions of

N2 atmosphere.

Features

- Cures bonds in a clean atmosphere (Class 100)

- The injection of N2 gas into the oven protects products and conductive bonds from oxidization (oxygen concentration : less 100ppm)

- Consists of 4-block heating zones allowing for each line to be independently contorlled. This enables the achievement of the desired temperaturee profile.

- Enaables rapid tempeerature rise via the supply of carriers directly into the inside of oven. This prevents film from forming on the surface of the conductive bond and prevents void generated by residual soslvent.

- Reduces equipment width by employing a 2-line carrying mehod.

- Facilitates cleaning of the inside of oven through a resractable upper oven body.

- Connects the In-line system to the pre and post processes.

Specification

| Compatible Works | SMD crystals, crystal oscillators |

|---|---|

| Heating Method | Heating via top & bottom rows of quartz heater |

| Loading Accuracy | Entrance : Conveyor (In-Line) Inside : Walking Beam Transfer Exit : Conveyor (In-Line) |

| Cleanness | less than Class 100 |

| Outer Dimension | W2800XD1400XH1700㎜ (excludes monitor and indicating light) |